- Back to Part Three

- On to Part Five

- Back to the main Alpha page

- More Projects

|

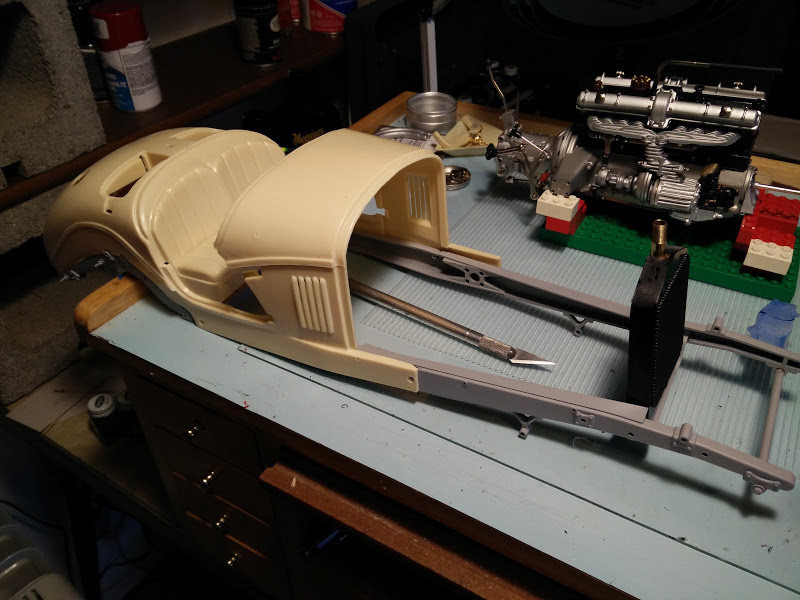

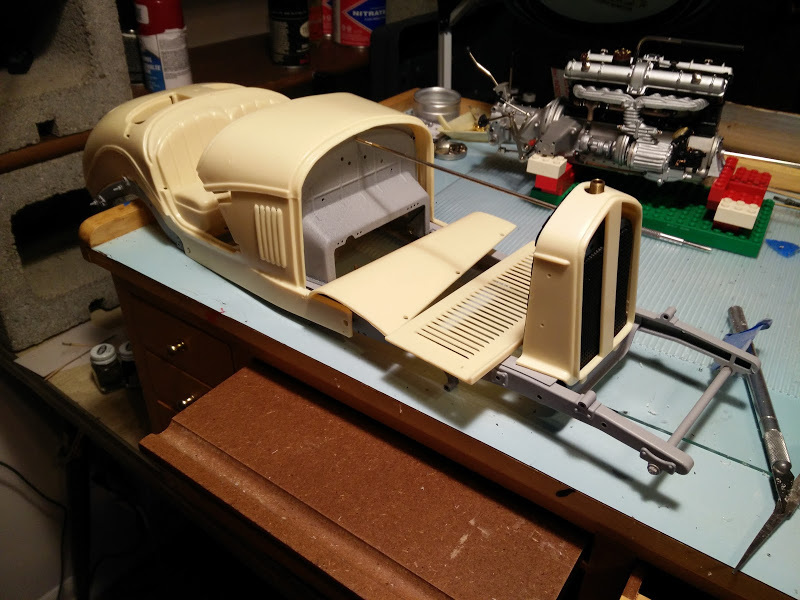

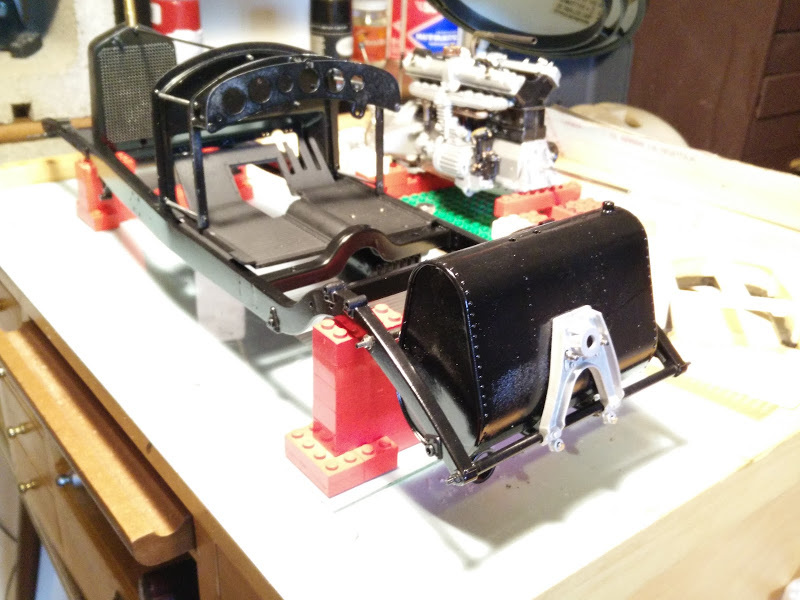

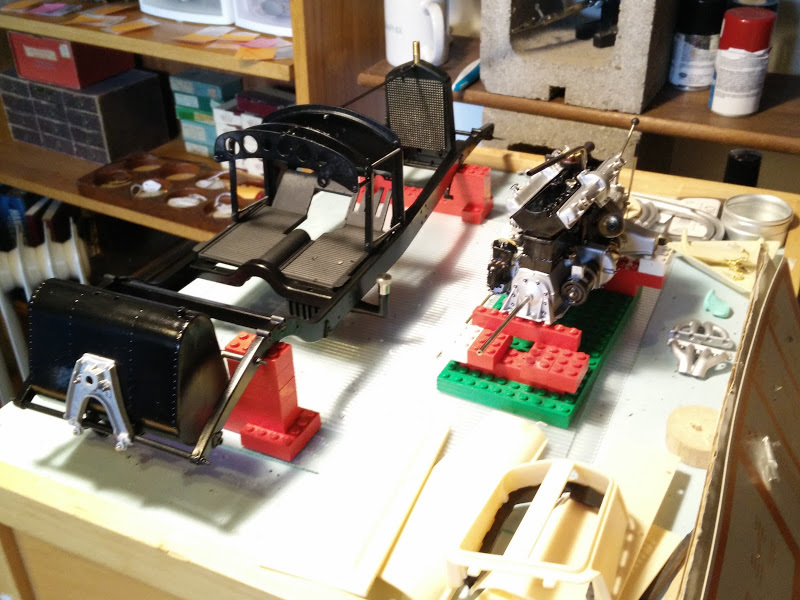

I primed the frame, plus a few other recognizable auto parts. It's at this point that something has to be done about issues involving major parts not fitting together (at all), before final paint of these pieces. Changes and alterations have to be made and I need to test the parts together to see how bad the problems are. They're bad.

But here we can see the scale of the thing. I'm going to need a bigger work surface. |

|

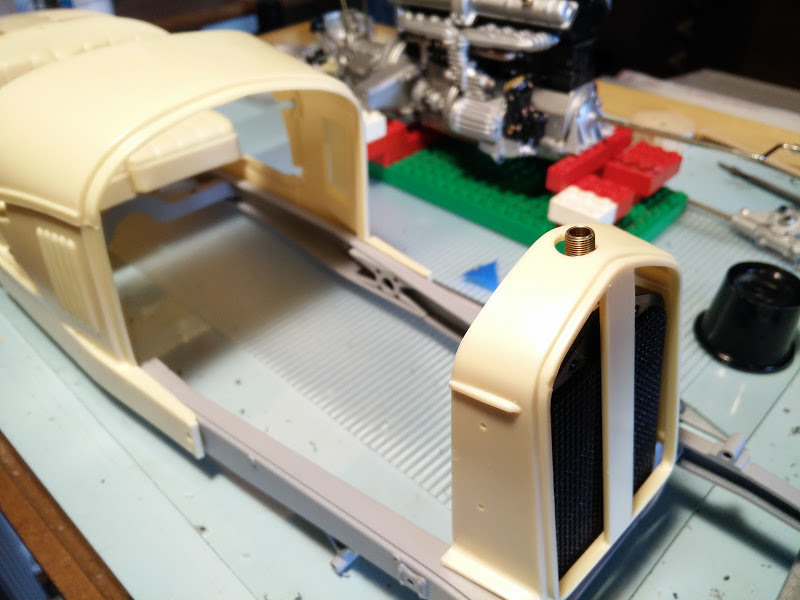

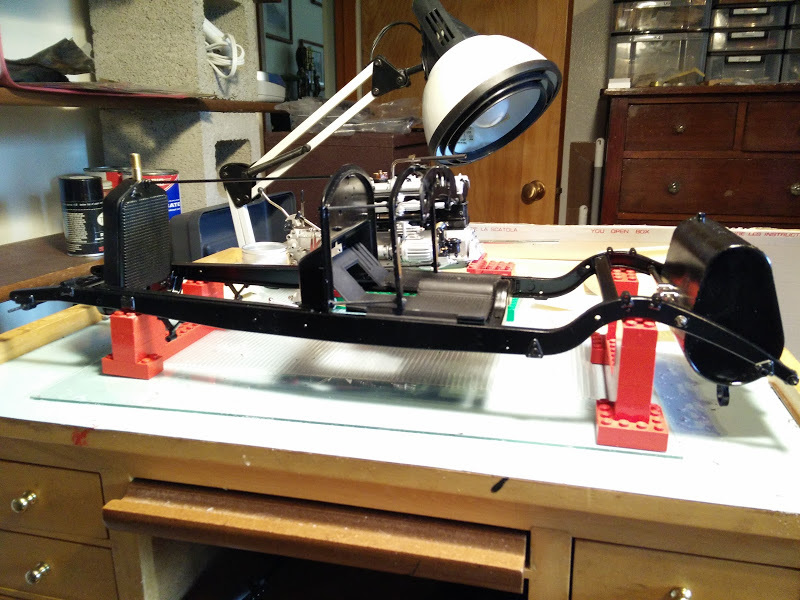

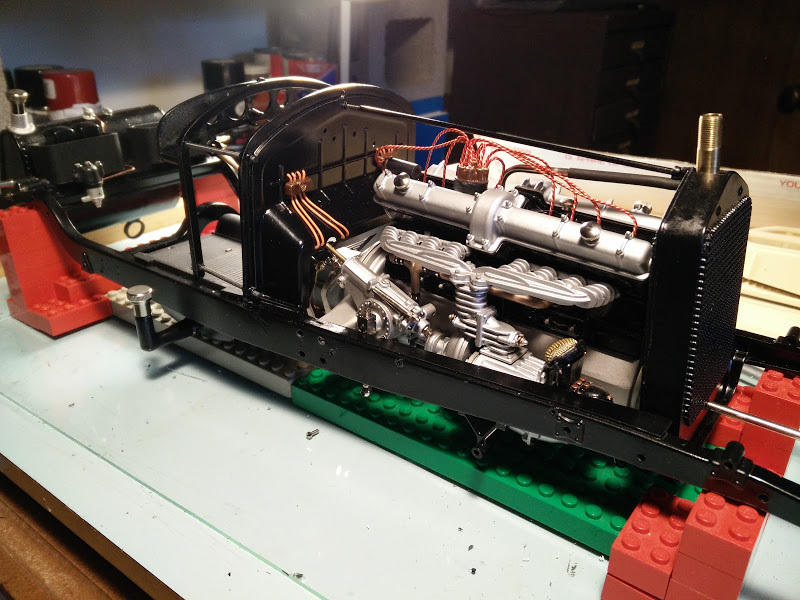

One well known problem with this Pocher classic is that assembled "as-is", and hood appears to be about a quarter of an inch too short. The hood is correct though. The real problem is that the radiator should tilt back at a significant angle. But assemble "as-is", or as directed, and the radiator ends up at 90 degrees. A secondary issue is that with the radiator at the right angle, the engine doesn't fit. It is too close at the front.

There are a few fixes to do; changing the angle on various connecting parts to the radiator, moving the engine back, and altering the radiator so the brass fill does not really connect to the hood ornament. To get the engine to fit requires a pretty significant change. But I am going to get that quarter inch by doing several smaller changes to everything. |

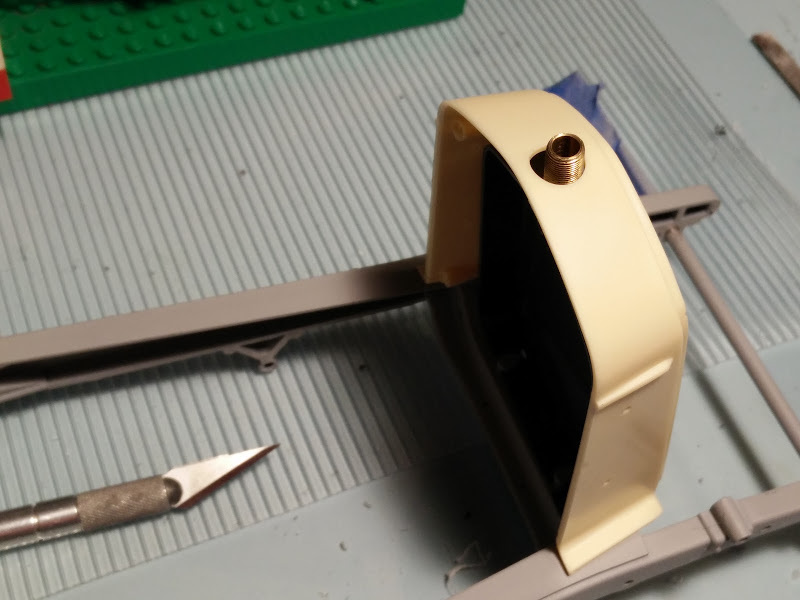

On the hood ornament, the brass part passes up through the nose body piece. This has to line up. By not having that part there, the nose can be shifted back enough to make the hood fit, but the radiator inside does not have to shift back so much that the engine doesn't fit.

Rather than leave that part out, I ground off one side of it's base. Now it sits closer to the back of the radiator. I can pass up outside the body, and the radiator can still sit ever so slightly forward. I haven't seen this suggested anyplace else, but it buys a couple of millimeters.

Rather than leave that part out, I ground off one side of it's base. Now it sits closer to the back of the radiator. I can pass up outside the body, and the radiator can still sit ever so slightly forward. I haven't seen this suggested anyplace else, but it buys a couple of millimeters.

|

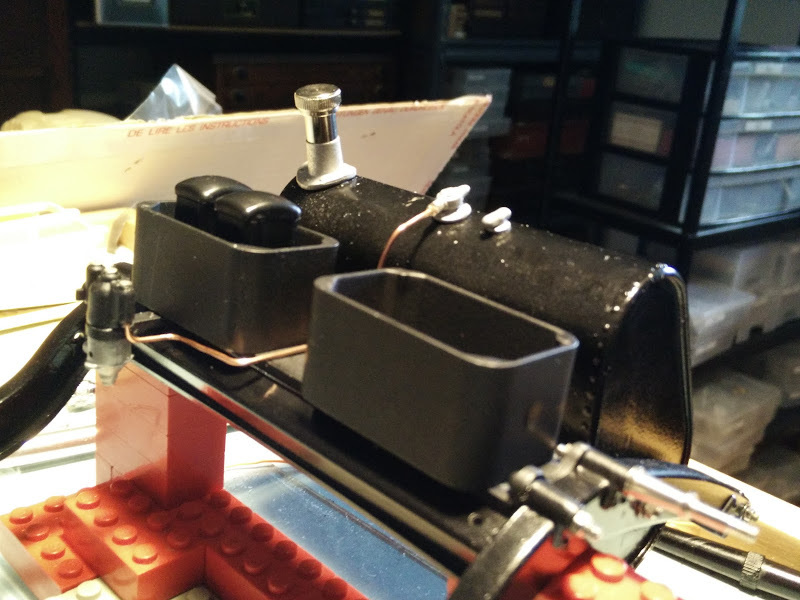

Next are some images of the fuel tank. Again, every little bit of this project takes a long time... In a Pocher kit, no parts really work as there are out of the box. The fuel tank and related pieces were no exception. It took quite a bit of sculpting, filing and carving to get it as good as it is (which is not that great). It is also time consuming because one must assemble many parts to check fit, and disassemble them all to make changes, over and over, and all before any painting.

|